PRODUCTS AND SERVICES

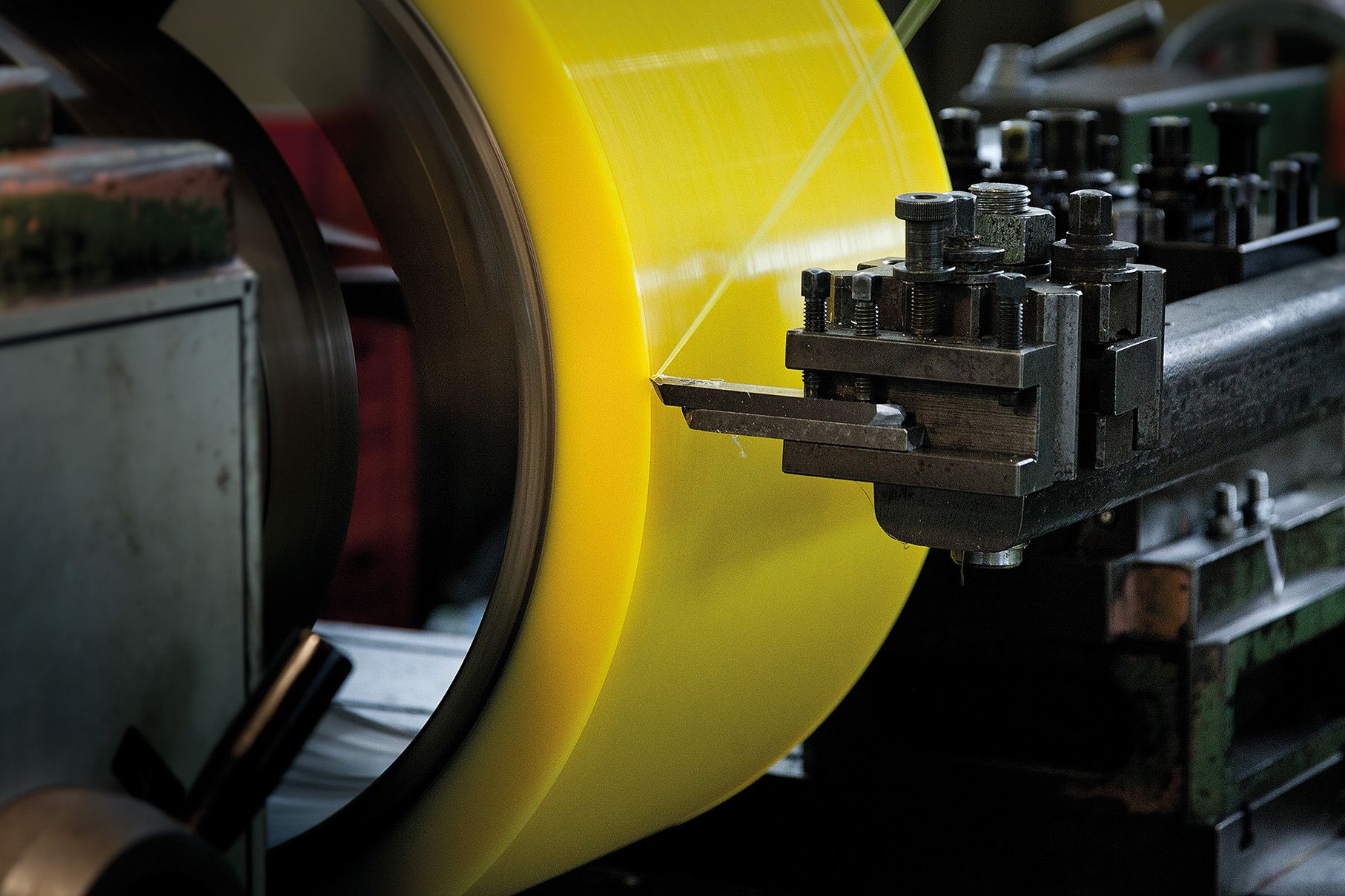

POLYURETHANE COATING OF ROLLERS

Pieffe is also specialized in polyurethane coating of rollers.

The production at Pieffe includes polyurethane coating for wheels, rollers, cylinders, and drums of any hardness and colour, with dimensions up to 1250 mm in diameter and 7000 mm in length. With a modern and well-equipped mechanical department, Pieffe offers its customers the supply of these coated articles, including custom or commercial metal cores and parts, the possibility of machining, the construction of dedicated and specific packaging, as well as potential shaft repair/reconditioning.

Pieffe also offers a wide range of machining options for polyurethane coatings, such as axial, radial, and helical grooves, conical, biconical, and crowned grinding, and the creation of integrated or fitted gutters.

Depending on the application areas and the mechanical or chemical stresses to which the rollers or wheels are exposed, we can use different types of coatings, offering various qualities, such as:

• Abrasion resistance

• Tensile strength

• Cut resistance

• Acoustic damping and stress damping for mechanical components

• Defined load capacity

• Resistance to linear, intermittent, and continuous pressures

• Chemical resistance to oils, greases, acids

• Resistance to paints, inks, gasoline, and petroleum solvents

• Stability when in contact with ozone

• Resistance to light and atmospheric agents

• High chemical and physical stability at specific temperatures.

Pieffe's expertise in polyurethane coating ensures that the products meet the specific requirements and demands of various industries, providing reliable and high-quality solutions for rollers and wheels used in diverse applications.

Do you need information?