PRODUCTS AND SERVICES

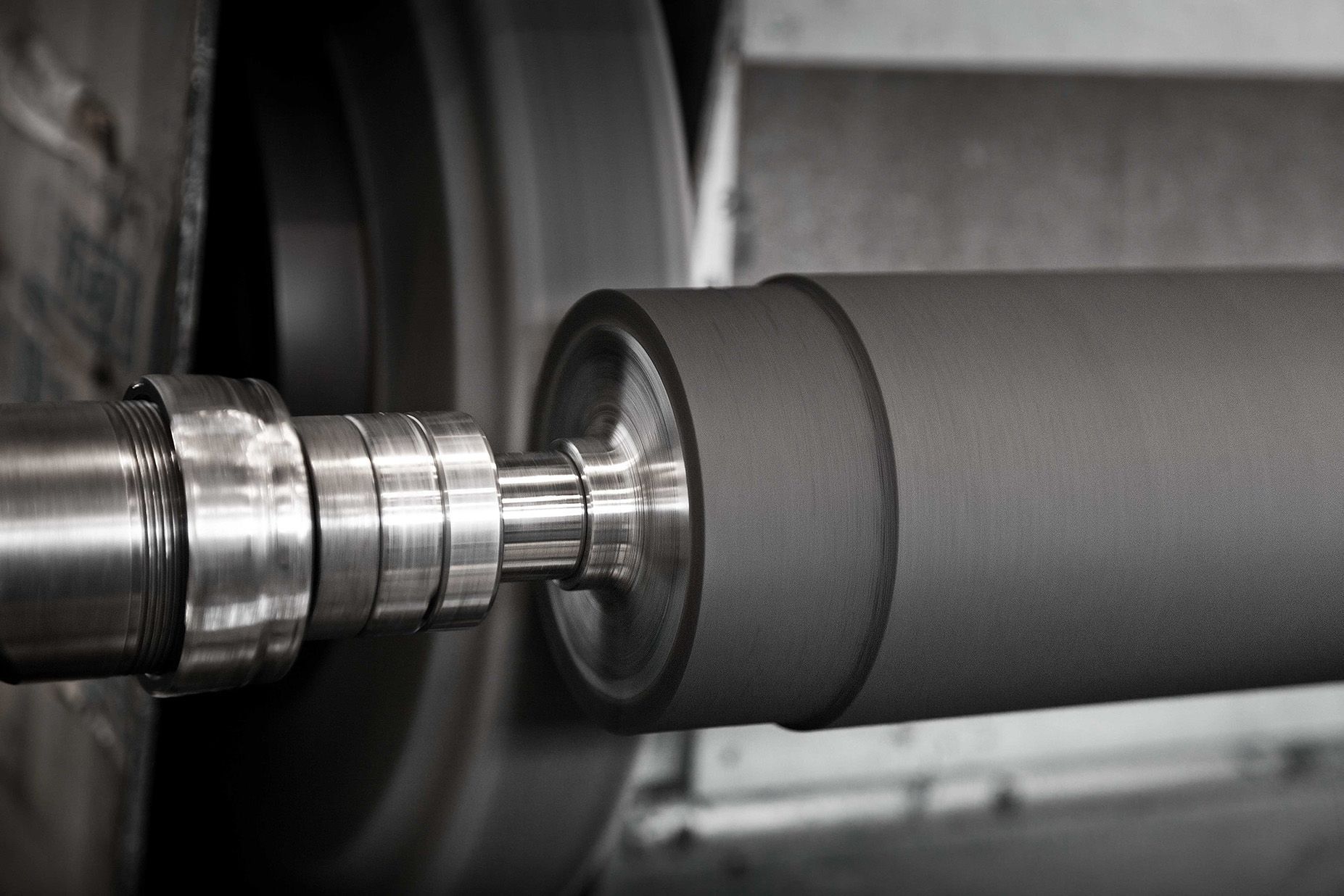

RUBBER AND SILICONE ROLLERS COATING

Pieffe's site in Mappano specializes in rubber roller coating, using different blends based on customer demands to meet various characteristics:

anti-abrasion, anti-wear, oil resistance, chemical resistance, high-temperature resistance, food-grade suitability, antistatic properties, and metal detectability. With decades of experience and material knowledge, Pieffe is capable of handling complex tasks on rubber cylinders, such as axial, radial, single and crossed helical grooves, conical, crowned, biconical, and double truncated grinding, as well as other specific requests, resulting in high-quality and competitive products in the market.

In 2023, Pieffe installed a sandblasting equipment, allowing the internalization of the entire production process, and offering complete control, flexibility, and faster delivery times. It is worth noting that Pieffe can regenerate used rollers by removing the worn rubber, treating the metal surface of the core, and applying a new coating, ensuring compliance with customer requirements. Pieffe can also restore bearing housings, recondition shafts and metal parts, or manufacture new ones, while providing suitable wooden packaging as needed. The ability to provide comprehensive roller services demonstrates Pieffe's commitment to offering top-quality solutions to its customers.

Do you need information?